Ford Ranger 2011-2023 front Street Series – T2 DBA2132S discs.

price per disc.

-

Diameter [mm]301,5

-

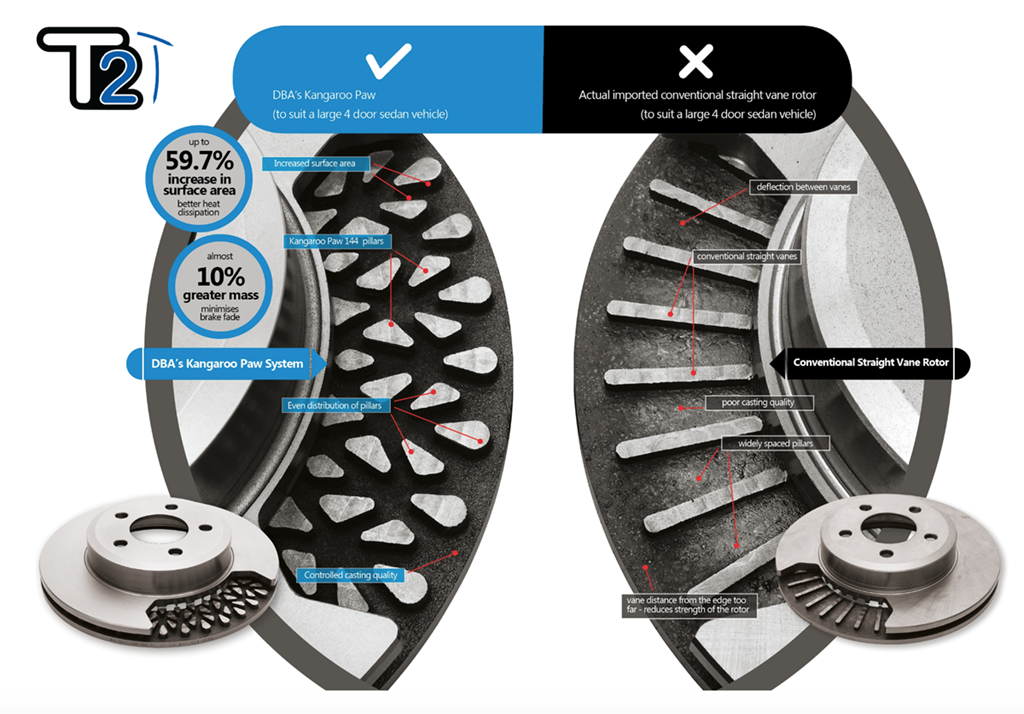

Disc VentKangaroo Paw

-

Number of Holes6

-

Inner Diameter [mm]98

-

Minimum Thickness [mm]30

-

Thickness [mm]32

-

Height [mm]60.7

-

Pitch Circle [mm]139.7

-

StageStage 2.

Products will normally be dispatched within 2-3 working days, delivery may take a few weeks if items aren’t in stock in the UK, however you will be contacted with a delivery estimate if this is the case for you after your order.

|

FORD

|

Ranger

|

2011-2019

|

2.2 TD 2WD (2011-2019)

|

Front

|

Brake Pads: DB2074

|

|

|

FORD

|

Ranger

|

2011-2019

|

2.2 TD 4WD (2011-2019)

|

Front

|

Brake Pads: DB2074

|

|

|

FORD

|

Ranger

|

2011-2019

|

3.2 TD 4WD (2011-2019)

|

Front

|

Brake Pads: DB2074

|

|

|

FORD

|

Ranger

|

2019-2023

|

2.0 TD 130BHP 4WD (2019-2023)

|

Front

|

Brake Pads: DB2074

|

|

|

FORD

|

Ranger

|

2019-2023

|

2.0 TD 170BHP 4WD (2019-2023)

|

Front

|

Brake Pads: DB2074

|

|

|

FORD

|

Ranger

|

2019-2023

|

2.0 Twin TD 213BHP 4WD (2019-2023)

|

Front

|

Brake Pads: DB2074

|

| Feature Description | Advantage | Benefit |

| Tri-Symmetrical curve slots dampens the vibration harmonics or noise | A quieter, responsive and smoother brake pedal feel | |

| Increased number of out-gassing exit points for brake pad friction gasses to escape through | Increases the consistency and effectiveness of every brake stop | |

| Universal slot design | Eliminates the need for left and right discs | |

| Increased surface area resulting in greater heat dissipation | Minimises brake fade and increases braking effectiveness | |

| Increased surface area resulting in greater heat dissipation | Prolongs service life for both pads and rotors. Reduces mechanical damage and associated costs | |

| An increase in thermal capacity property allows the rotor to handle constant extremes of heat over extended periods of time | Minimises warping and cracking and prolongs the service life of the rotor | |

| Special formulation designed to respond to DBA’s TSP process | Minimises warping and cracking and prolongs the service life of the rotor | |

| Heat paint markings change colour at specific temperature thresholds | Offers the driver a clear indication of peak braking temperatures | |

| When temperature thresholds are exceeded paint markings will permanently change colours | Allows the driver to monitor rotor fatigue and decide on rotor replacement and to assist resellers with warranty claims | |

| Reduces corrosion | Stops any unsightly rust formation | |

| Enhances appearance | Adds value to the product |